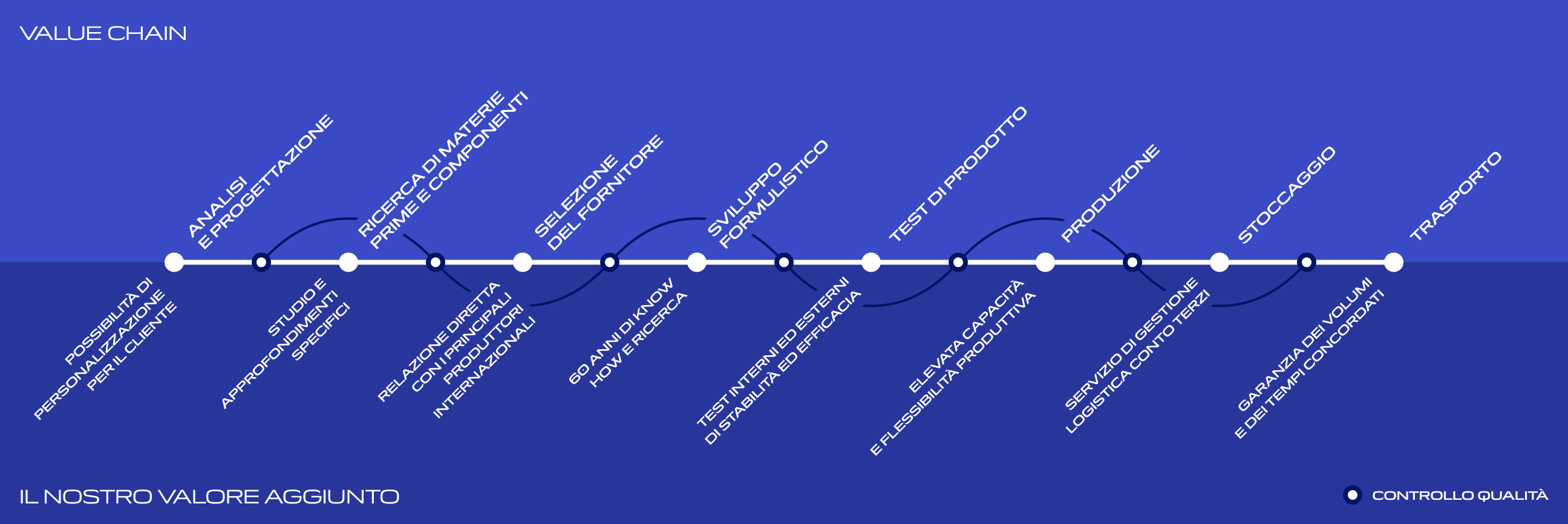

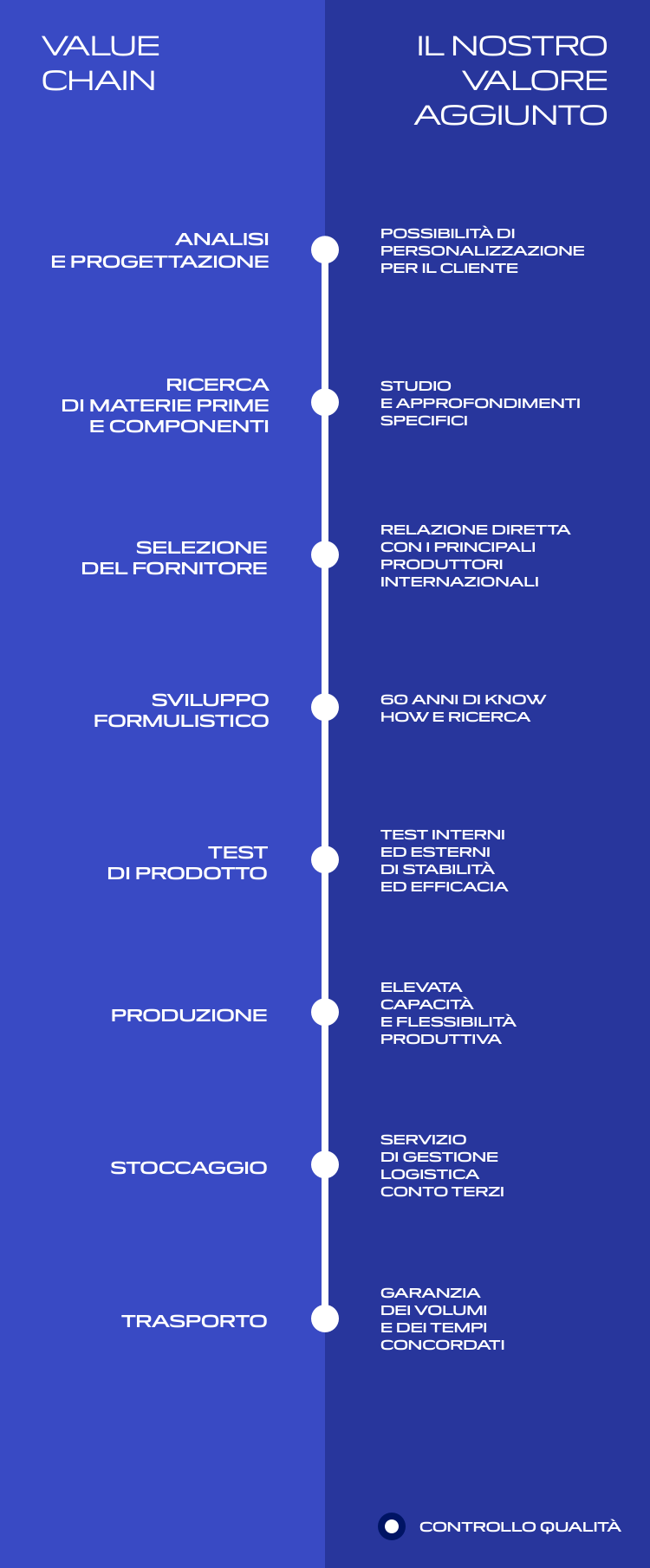

FROM ANALYZING YOUR NEEDS TO A GREAT RESULT.

Every product we produce comes from our careful and constant listening to our clients' needs and from an in-depth analysis of the market.

We work with the client throughout the entire process of creating the product: concept and formulation, packaging and industrialization.

We share experiences and skills with the main players of the industry to innovate on raw materials and components.

We manage the entire production process directly: from the concept to the chemical formulation, from bottling to labelling. This way, we can guarantee top quality for our products, which is monitored throughout the chain.

Thanks to our lean supply chain, we can respond to every need quickly and flexibly.

The entire production process is carried out, checked, and managed inside MK's production plant, which covers an overall surface of 20,000 sqm. Our manufacturing capacity equals 45 million kg/year.

MK caters to every one of your needs. If you need a customized and unique product even in the packaging, you can count on us. Our Graphic & Print Department was conceived to help clients create and print made-to-measure labels that are customized both in content and graphic design.

Italiano

Italiano